Main Cost Structures of Battery & Power Connectors

The cost structure of battery connectors and power connectors is influenced by multiple factors tied to design, materials, manufacturing, and market application. Here’s a breakdown of the main cost components for both:

🧾 Main Cost Structures of Battery & Power Connectors

| Cost Component | Description | Impact Level |

|---|---|---|

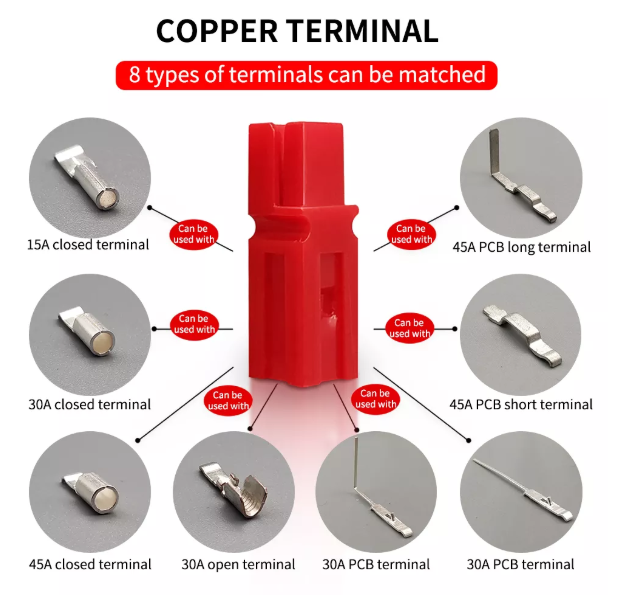

| 1. Raw Materials | Copper (for contacts), plastic resins (like polycarbonate/ABS for housings), silver/tin plating | 🔺 High |

| 2. Contact Design & Size | Larger current = bigger contacts = more material. High-amp connectors need silver/tin-plating for conductivity | 🔺 High |

| 3. Manufacturing Process | Injection molding (housing), stamping/machining (contacts), plating, and crimping | 🔺 Medium |

| 4. Labor & Assembly | Human or robotic assembly of connectors, especially for high-precision or custom parts | 🔺 Medium |

| 5. Tooling & Molds | High initial investment in molds, especially for custom designs or high-volume products | 🔺 Medium |

| 6. Compliance & Testing | Certification costs: UL, CE, RoHS, REACH, flame retardancy, etc. | 🔺 Medium |

| 7. Packaging & Logistics | Bulk packaging vs. individual kits, international shipping (adds customs/import costs) | 🔻 Low-Medium |

| 8. R&D / Design Costs | For specialized connectors or IP-protected designs | 🔻 Low-Medium |

| 9. Volume & Economies of Scale | Higher production volume = lower per-unit cost. Custom or low-run = higher price. | 🔺 Very High (per unit) |

| 10. Branding & Distribution | Premium brands cost more due to reputation and certified quality | 🔺 Medium |

🧪 Example: Cost Drivers by Connector Type

🔋 Battery Connector (e.g., SY350, XT60)

-

Key Cost Drivers: Contact size, current rating, housing durability, plating type

-

Typical Range: $2 – $15+ per unit (higher for heavy-duty, branded versions)

⚡ Power Connector (e.g., DIN, Powerpole, Circular Industrial)

-

Key Cost Drivers: Pin count, environmental sealing (IP ratings), locking mechanism, standards compliance

-

Typical Range: $1 – $50+ depending on complexity and application (e.g., aviation, medical, industrial)

💡 How to Reduce Connector Costs

-

Choose standard, high-volume models

-

Avoid over-specifying current/voltage beyond actual need

-

Source off-brand equivalents for non-critical applications

-

Use modular designs where possible to reduce tooling